Video

Description

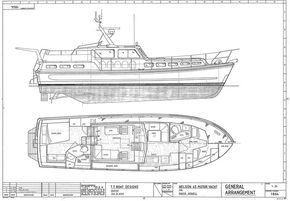

Seaward Sapphire is a rare example of a meticulously restored 1991 4/6-berth Nelson 45 motor yacht, a classic fast seagoing craft built for safe passage in any weather.

The vessel has recently completed a comprehensive refit, with scrupulous attention to the original design detail and aesthetics.

From the bilges to the top of the mast head, each element has been restored, refurbished or replaced, with systems and accommodation upgraded to modern expectations, making Seaward Sapphire one of the finest examples of the Nelson 45 around today.

Seaward Sapphire is now available for viewing, by appointment. A full survey and insurance valuation was carried out in August 2023 and this will be made available on request. She is currently being prepared for the 2024 season, and is now offered at a revised price. For further information, photos, specifications, walk-throughs and sea trials video, please visit www.seawardsapphire.com or contact the owners.

Specifications

| Vessel type: | Semi displacement motor yacht |

| Designer: | Arthur Mursell, TT Boat Designs |

| Builder: | Seaward Marine Ltd |

| Make: | Nelson |

| Model: | 45 |

| Fit Out: | Seaward Marine Ltd |

| Constructed: | 1991 |

| HIN: | Yard Number DH45 |

| Registration: | SSR42674 |

| Registry: | Maritime and Coastguard Agency |

| Berths: | 6 |

| No. of engines: | 2 |

| Engine model: | Ford Sabre |

| Engine power: | 740 |

| Engine hours: | 1218 |

| Fuel type: | Diesel |

| Drive type: | Shaft drive |

| Length over all: | 13.84m |

| Beam: | 3.9m |

| Maximum draft: | 1m |

| Bridge clearance: | 5.45m |

| Hull material: | Glass Fibre |

| Hull type: | Semi displacement |

| Hull colour: | Blue |

| Displacement: | 15 metric tons |

| Fuel capacity: | 2000 Litres |

| Water capacity: | 1000 Litres |

| Holding tank capacity: | 88 Litres |

Accommodation

INTERIOR

The interior surfaces of the hull and deckhead have been accessed in virtually all areas for a complete clean, de-grease and re-paint. The deckhead has been insulated throughout with PIR insulation board, and the engine room with Quietlife foil faced insulation with polymeric barrier.

The interior has been fully refurbished, with all new teak veneered cabinetry in the galley, and the original teak furnishings re-built or restored throughout the rest of the boat. The new sole boards are teak veneered on marine ply, and all soft furnishings newly reupholstered with fire retardant fabric.

Sleeping accommodation is provided for 4 in two private ensuite cabins, each with ample locker storage, ventilated bed bases and individual reading lights:

Aft cabin with owners’ double bed to port; starboard ensuite with walk-in thermostatic shower enclosure with Whale automatic pump-out, shower seat and teak slatted floor; Corian style moulded basin unit and Tecma ceramic freshwater electric flush WC; double upholstered seat (or child’s bed) to starboard.

Forward cabin with V berth; ensuite with thermostatic shower with Whale automatic pump-out and teak slatted floor, Corian style moulded basin unit and freshwater electric flush WC. This WC is connected to the black water holding tank, with optional pump-out (dockside or offshore to the sea).

All supply and waste to the ensuites has been replaced; WCs are connected to rigid waste pipe with flexible connections at each end.

Additional double sleeping accommodation is available in the dining area, aft of the forward cabin.

GENERAL INTERIOR LAYOUT:

From the upper helm, a pair of glazed teak companionway doors leads down to the extensively glazed wheelhouse/saloon, with triple windscreen and side glazing giving excellent all-round visibility.

The main helm is forward and to port, and the navigator’s station to starboard, both having Bremshey fully adjustable suspension seats with seat belts.

Saloon seating is located behind these and to starboard, with two chart drawers under, and the Fusion RA60 music centre and main central heating controls adjacent to the companionway steps.

To port, behind the main helm is a teak 2 door, 2 drawer cabinet for bottles glasses and storage.

Centrally placed steps lead forward from the saloon down to a completely new galley located on the starboard side. The dining area, rise and fall table, and U shaped upholstered seating with reading lights, lie to port.

A 3.8m white Corian style worktop carries an inset compact stainless steel sink/drainer and 4 zone Neff induction hob with stainless steel splashback. Sited below the induction hob is a Neff stainless steel multifunction oven with pan drawer under. Flexible worktop storage for laundry is provided, via a gas lift panel set within the worktop to the right of the sink.

A run of storage cupboards with gas lift doors, with stainless-steel microwave located to the right of the sink, completes the back of the worktop.

Below, to the left of the oven is a narrow 5-drawer stack, to the right a cupboard space for either a compact washing machine, compact dishwasher (plumbing and power present) or additional galley storage.

Adjacent to this is an under-sink cupboard with a stainless steel dual voltage Dometic Coolmatic CR140S 136 litre compressor fridge/freezer to the right. This is connected to the boat’s electrical systems via a Waeco rectifier/inverter which provides automatic switching between 240VAC (prioritised) and 24VDC.

A pull out shelving stack returns the worksurface to the galley newel post. Positive latching of drawers and cupboards is provided by 316 stainless steel push-pull catches.

Upper helm - with canopy stowed, view towards companionway to saloon, showing Besenzoni pedestal seats and teak laid deck

Upper helm, canopy fitted - view down companionway steps to saloon-wheelhouse, with upper helm station to starboard

Saloon, full of light and great views! Helm positions fwd, seating to starboard, with chart drawers under drinks cabinet, to port

Wheelhouse, showing main helm with navigation, instrumentation and switches to port and co-pilot station to starboard

Saloon seating stbd, looking aft, Fusion RA60 Marine Stereo set in aft bulkhead, with central heating controls adjacent to companionway steps

Galley - view from dining area, showing teak veneered base and locker units, oven, hob, fridge-freezer

Galley - view fwd, showing compact stainless steel sink and drainer set in machined Durasein solid surface worktop

Galley - dining area. with switched stainless steel reading lights. The table can be lowered to make up a double bed

Fwd ensuite - electric flush WC, Durasein solid surface countertop and basin and slatted teak shower tray insert

Aft ensuite - basin and shower with recessed thermostatic controls. Central heating fan unit located below basin unit cupboiards

Construction

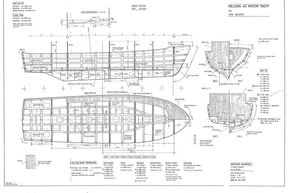

The Nelson 45 is an exceptionally well constructed and robust vessel (see photo gallery for original design drawings, courtesy of Arthur Mursell, TT Boat Designs, and further detail on the website www.seawardsapphire.com).

The hull and decks are heavy GRP, stiffened by substantial watertight bulkheads, ribs and longitudinal stringers, with heavy duty steel cored engine bearers framing the two keel fuel tanks.

Topsides are finished in blue gel coat with the original varnished teak rubbing strakes and classic Nelson teak detailing fitted to the top sides and transom.

Decks: fore and side decks are laid with Treadmaster with teak trim, the afterdeck is solid teak laid, restored and re-caulked. The deck edge is protected by the distinctive Nelson heavy duty commercial black rubber D-fendering, re-bedded with Soudal HS 270 structural adhesive.

The windows are framed in aluminium alloy, glazed with toughened glass and all re-bedded with Soudal HS270.

The underwater area is finished in red commercial antifouling with a white gloss boot top. Cathodic protection is provided by a pair of 200mm hull anodes through-bolted to bonding cable connecting the engines, P-brackets, prop shafts, rudders and bronze skin fittings. All bonding cable has been checked and renewed as necessary and tested with an ohmmeter for continuity. New collar anodes are fitted to prop shafts and new dedicated anodes to the SPURS rope cutters.

The fine entry, rounded hull form and flatter after sections give the vessel its superb sea-keeping qualities

The fine entry and flattened curves of the after sections make for a fast semi-displacement hull form

Wheelhouse - typical Nelson 45 triple windscreen with Wynn straightline Type C wipers with screenwash

Equipment

DECK AND HULL EQUIPMENT:

Lewmar hatches to foredeck (2), coach roof (2) and afterdeck (1) with Skyshade blinds below.

Stainless steel pulpit with stainless steel side rails; aft rails varnished teak on stainless steel stanchions. Cabin top and wheelhouse grabrails are stainless steel tube.

Lofrans FALKON windlass operated by deck mounted foot switches and controlled by a 70amp breaker at the main 24VDC breaker panel. Anchor: 60lb CQR shackled to 50m of 10mm galvanised short link chain leading through a chain pipe into a locker in the fore peak with internal hatch access. Bow roller: heavy duty stainless steel with Nylon roller.

The rest of the deck fittings, fairleads and mooring cleats are all heavy duty alloy.

A white painted alloy mast is fitted to the coach roof, carrying navigation lights.

At the stern is a pair of Whittall stainless steel davits, with Avon 3m RIB included; Stainless steel and teak aft bathing platform/boarding ladder; 8 fender baskets fitted at the stern with new fenders and fender socks.

An emergency steering gear access point is located on the starboard side forward of the transom, colour coded yellow and labelled. Fuel inlets, colour coded red and labelled, are located in the port and starboard side decks. The water inlet, colour coded blue and labelled, is located in the port side deck. A dockside black water pump-out is located in a deck locker port side deck, forward.

UPPER HELM:

Fitted with an alloy windscreen glazed with toughened glass and Besenzoni pedestal seats for helm and co-pilot.

The Upper helm station is to starboard with stainless steel wheel, Kobelt throttle controls, start/stop for both engines, horn, upper instrument/navigation panel and bow thruster joystick.

Navy canvas canopy on stainless steel tube frame, with spray dodgers fitted around the aft deck.

LIGHTS

All operated from the wheelhouse as follows:

Search light mounted forward on the wheelhouse roof; aft facing fixed spotlight with LED lamp; port and starboard LED navigation lights mounted on the wheelhouse roof; steaming light, all-round white light and stern light all with LED lamps mounted on the mast.

Red night lights in wheelhouse and galley and red flexible chart light at the stbd nav station.

GENERAL EQUIPMENT AND FITTINGS:

Fiamm Horn: mounted on the wheelhouse roof and operated from the wheelhouse and upper helm instrument panels; 3 x Wynn straight line marine window wipers, Type C, operated from the wheelhouse instrument panel, serviced; screen wash operated from the wheelhouse instrument panel, stripped and serviced, with new supply pipework.

STEERING GEAR:

Dual helm with hydraulic pumps to each wheel, plumbed with copper and flexible hose connections to the hydraulic ram located in the aft cabin steering compartment.

A pair of stainless-steel rudders are fitted through glassed-in tubes and lip seals with remote greasers. Provision is made for emergency steering in the event of hydraulic system failure, with access points through the top of the steering locker, out through a colour coded (yellow) and labelled screw cap in the aft deck, with drive rods stored under the aft cabin bed base boards.

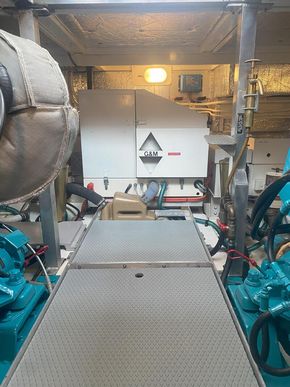

GENERATOR:

A G&M 4.2Kva generator set is installed within a sound insulated steel casing at the aft end of the engine room, powered by a Volvo 2001 direct raw water-cooled single cylinder diesel engine and generating 230V AC at a fixed 3000rpm. Fuelled from the aft keel tank. Cleaned, repainted, fully serviced with new engine mounts, exhaust elbow, pencil anode, wiring, oil & filter change.

Generator starting is via an all new 12V dedicated starting battery & battery box, with isolation switch and fuse, independent of the main battery banks. To avoid self-discharge during prolonged periods of inactivity, a new Victron Orion 24V to 12V battery-to-battery charger is fitted.

Cooling is direct via a dedicated bronze generator seacock on the port side, stripped and serviced. The system has been dismantled, flushed and serviced and a new raw water impeller fitted.

The wet exhaust incorporates a Vetus water lock, muffler and gooseneck, discharging through the starboard topside at the waterline. All stripped and serviced with new exhaust hose & jubilee clips as required.

Almost immediate starting from cold; test run showed a steady 230VAC.

BOW THRUSTER:

Max Power CT60 twin propeller 24V bow thruster, powered by a new battery installation comprising: a pair of new 12V batteries connected in series, fitted under the forward cabin berth in a dedicated battery box and charged via a 24V-to-24V split charge relay controlled by a 70A breaker on the 24VDC panel. The circuit is protected by an overload fuse and master switch.

The bow thruster compartment is vented by the new bilge ventilation system with fire protection provided via a new fire port situated between the two V-berths, following surveyor's advice.

Joystick bow thruster controls are fitted at both the wheelhouse and upper helm stations.

GALLEY EQUIPMENT:

All new galley, with AC equipment, apart from the fridge freezer which is dual voltage (230V AC and 24V DC), comprising:

Corian type solid surface worktop with teak veneered drawers and cupboards above and below and stainless steel compact inset sink/drainer.

Neff multifunction oven and grill; Neff 4 zone induction hob; stainless steel microwave.

Space for compact washing machine/ dishwasher with 240V supply and plumbing/waste.

Dometic Coolmatic stainless steel CR140S 136 litre compressor fridge/freezer dual voltage 240VAC or 24VDC with Waeco rectifier/inverter (240V prioritised to maximise benefits of shore power)

ENTERTAINMENT EQUIPMENT:

Fusion RA60 2-zone marine stereo with Bluetooth, mounted aft saloon by companionway steps, with 3 pairs of speakers – 2 aft cabin, 2 saloon, 2 galley.

BILGE PUMPS

6 automatic bilge pumps, located in galley keel space (1), engine room (4), aft cabin centre bilges (1), with manual over-ride switches at main helm.

2 automatic bilge water alarms port and starboard bilges in engine room, with alarm panels and test buttons at the lower helm.

Manual bilge pumps in galley with terminals in galley, engine room and aft cabin.

Lofrans windlass, bow roller assembly and anchor; teak gunwhale detailing and heavy duty alloy fairlead

Engine room air intake cowls, five each port and starboard; these have internal air shut-off flaps, operated from the saloon

Heavy duty deck cleat and fairleads, aft, port quarter, emergency steering access visible to the right of the image

Steering - hydraulic steering and autopilot unit, main helm, engine room, port fwd bulkhead; remote operated fire extinguisher just visible to the right; 75mm bilge extract duct below

Steering - steering gear locker, aft cabin, showing hydraulic ram, stbd steering arm and link & tubular heater

Bilge pumps - sender for high bilge water alarm (centre), stbd bilge, engine room, fwd. Also visible, just aft of this, Raymarine speed/temperature transducer

Diesel fired hot water central heating unit, showing 22mm speedfit flow & return ring circuit top left. Located engine room starboard. Above right, stbd engine room fan unit

Fresh water systems - calorifier, high pressure pump, accumulators. Also, central heating speedfit ring circuit. Stbd side

Fresh water tanks, cleaned, view through from galley to fore cabin, showing layout; new H&C supply to fwd ensuite to right, new tank breathers (black) to left

Starboard battery bank with new Victron 40A charger above, main fuse box/switches to right and generator exhaust system below left

Port battery bank with generator starting battery to the left; Victron Orion 24V - 12V charger top left

Navigation Equipment

NAVIGATION EQUIPMENT

Electronic navigation equipment has been rationalised around a recently installed Raymarine autopilot, and all Raymarine instruments daisy chain linked by Seatalk cables.

Installed equipment as follows:

• Sestrel magnetic compass wheelhouse mounted.

• Furuno Model type 1930 open array radar 0.25 – 26 mile range, mounted on the wheelhouse roof forward of the mast; display in wheelhouse.

• Raymarine ST7002 autopilot, wheelhouse mounted with fluxgate compass mounted under forward seating in galley.

• Raymarine C90 GPS/plotter wheelhouse mounted.

• Raytheon ST60 Tri data instrument – speed/log/depth wheelhouse mounted.

• Raymarine ST60+ depth instrument mounted upper helm with depth transducer aft of the port engine.

• Raymarine ST60 electronic compass mounted upper helm

• Raymarine ST60+ speed/log mounted upper helm with speed/temperature transducer mounted forward of the starboard engine.

• 2x GPS domes mounted on the mast, not currently in use as GPS integral to plotter.

• NASA Target Navtex-pro-plus mounted wheelhouse starboard navigation desk.

VHF EQUIPMENT:

• Icom IC-M56 VHF radio with handheld speaker – mounted on the wheelhouse starboard navigation desk.

• Navico Axis RT1200 VHF radio with handheld speaker mounted at the upper helm.

Upper helm - Raymarine speed, compass & depth instruments; P & S engines temp, oil pressure, RPM, start-stop; rudder indicator, horn & bow thruster

Tridata display (rt), Port engine rev counter (mid), bilge pump over-ride switches (left), Sestrel compass (top)

Engine(s)

The engines are installed in an enclosed engine bay beneath the wheelhouse, accessed via a floor hatch with gas lift. There is good access all round for servicing. Their flexible engine mounts are bolted to substantial glassed-in longitudinal steel engine beds (see original design drawings, courtesy of Arthur Mursell, TT Boat Designs).

Engines are the original Sabre Lehman type 370HP turbo charged 6-cylinder straight diesels in excellent condition, fully cleaned and re-painted in the original Turquoise BS5018. Engine oil, oil filters and fuel filters (2 engine mounted fuel filters and one Racor filter/separator per engine) changed, with new fuel hose as required. Port engine serial no. B9137, hours logged 1209. Starboard engine no. B9138, hours logged 1218.

Starting from cold during sea trials and land-based test work was immediate.

The engines are coupled to MG 507A Twin Disc gear boxes with stainless steel 1¼” prop shafts running through sealed and water lubricated grease packed stuffing glands (re-packed), and, outboard through cutlass bearings set within substantial bronze P-brackets.

The propellors are 3-bladed 26”x27” bronze in perfect condition. The ‘SPURS’ rope cutters have been removed for cleaning, the prop shafts checked and found clean and free of corrosion and the rope cutters replaced with new bushes and anodes.

Cooling is indirect, via raw water heat exchangers, with heavy duty bronze raw water intakes fitted with stainless steel strainers, new raw water hose & clamps, and new impellers. The heat exchangers have been stripped, checked for corrosion, found to be in excellent condition and re-assembled.

The wet exhausts discharge via main 5” exhaust pipes port and starboard through underwater outlets, making for quieter running when under way. Secondary exhaust pipes discharge at the waterline, ensuring exhaust back pressure is minimised when the engines are idling.

Crankcase breather pipes (new) are fitted to the rocker box covers and vented through the topsides. During sea trials and land-based tests no oil residues issued from the vents, indicating satisfactory crank case pressure and little blow-by from the pistons.

Throttle and gearbox controls are Kobelt 2090 push-pull remote controls stationed at the wheelhouse (main station) and at the upper helm (slave station). A control panel with start/stop and warning gauges for each engine, as well as navigation instruments and bow thruster controls is located at both upper and lower helm stations.

Engine room - view down from wheelhouse hatch, with generator aft of the central gangway (bottom of the image)

Port engine, view fwd, showing injector pump, engine sump oil pump-out tap, oil filter and chromed rocker box cover

Fuel sampling pump and valves; air intake filter to the right, turbocharger and exhaust shield behind

Exhaust system, port engine, showing main 125mm exhaust pipe & secondary exhaust pipe discharging to waterline

Bronze raw water seacock and strainer for port engine, new hose double band clamped, generator raw water seacock and water cooled prop shaft bearing

Safety Equipment

SECURITY AND FIRE:

• Fire extinguishers: AFFF as follows: upper helm 6kg, saloon 2kg, galley 2kg, fore cabin 2kg; dry powder as follows: upper helm 2kg, saloon 2kg.

• A fire port is fitted to the fore cabin between the V-berths to enable firefighting in the enclosed bow thruster area.

• Seafire fire extinguisher in engine room – fixed installation operated from saloon.

• Emergency air shut off levers for port and starboard engine room air intakes operated from saloon.

• Kidde carbon monoxide alarm fitted in engine room.

Location Map

Note: Indicated location is approximate general area only.